Guardian HDF – Gas Spring Protective Cover

Effective Protection for Gas Springs in Dirty Environments

Hyson's Guardian™ High Density Fabric (HDF) serves as a protective cover for Gas Springs, encompassing the rod and securing to the body. This design ensures protection against contaminants while in use, extending the life of the springs. Specially created for integration in challenging settings, the HDF lessens the danger of contamination ingestion and offers a straightforward installation process.

Benefits of HDF

- Seals spring from contamination and ingestion

- Reduces unexpected production downtime

- Improved part reliability

- Many mounting options

- Available for gas springs with a service thread in the piston rod

How to Install

The top of the HDF cover is a thin metal baseplate that screws into the top of the gas spring rod and adds about 10 mm (0.39 in) of length to the spring. The cover itself is attached to the baseplate and sized based on cylinder width, then cut to length and secured at the bottom during installation. Because the baseplate adds 10mm of length, the HDF should be installed on an application where the stroke of the gas spring can utilize the additional 10mm.

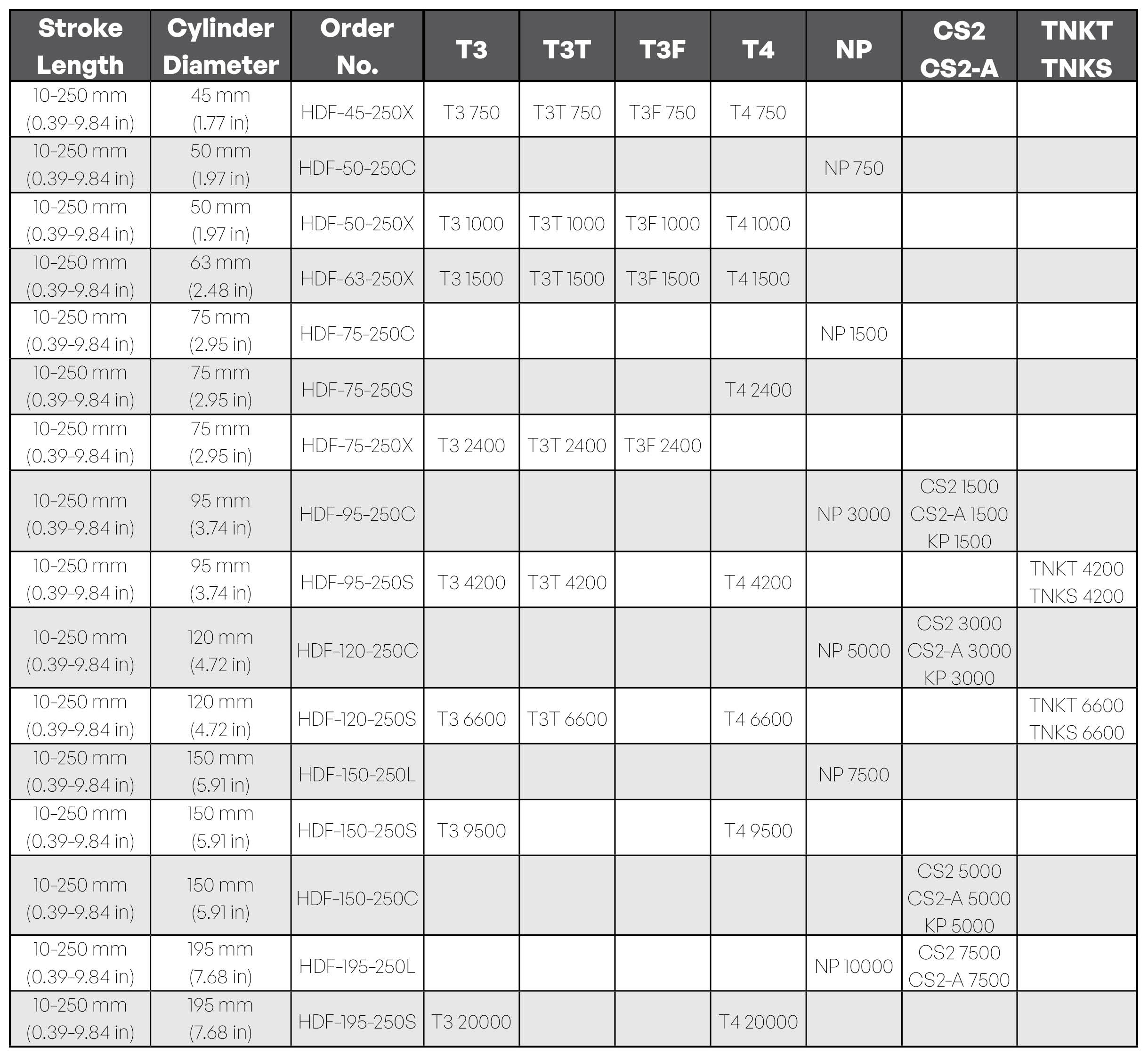

Compatibility

Hyson now offers seven size options of HDF covers to fit most Gas Springs used in hot stamping, electric vehicle manufacturing, and other extreme environments.

Industries Served

These HDF covers are ideal for industries that use hot stamping for ultra-high strength steels (UHSS), such as EV/AV manufacturing, to protect against the boron scale and other contaminants that could impact the Gas Springs ability to operate. The process of hot forming is growing trend for manufacturers to help reach their goals of developing lightweight solutions

against the boron scale and other contaminants that could impact the Gas Springs ability to operate. The process of hot forming is growing trend for manufacturers to help reach their goals of developing lightweight solutions

New lighter-weight materials often used in EV production require hot stamping. With Hyson’s hot stamping solutions, you get high-quality stamping in hot applications, tools that can withstand harsh environments and conditions, and the most technologically advanced safety features in the industry.

Technical Performance

| Operating Temperature: | 0 to 80°C (32 to 176°F) |

| Temperature Resistance: | -30 to 150°C (-22 to 302°F) |

| SPM according to the gas spring. |

Flange Adapter

If the gas spring is flange assembled, an additional item – called a flange adapter HDFF – must be used. The flange adapter must be assembled at the top of the flange with the flange assembly screws. Make sure to use the right flange adapter model for the cylinder size, according to the table below.

*Note: The Flange Adapter can only be combined with the flanges in the table below.

|

Cylinder Size |

For Flange |

Order No: |

|

Ø 45 mm (1.77 in) |

FCS 500 |

HDFF–45 |

|

Ø 50 mm (1.97 in) |

FCS 750 |

HDFF–50 |

|

Ø 63 mm (2.48 in) |

FCSX 1500 |

HDFF–63 |

|

Ø 75 mm (2.95 in) |

FCS 1500 |

HDFF–75 |

|

Ø 95 mm (3.74 in) |

FCS 3000 |

HDFF–95 |

|

Ø 120 mm (4.72 in) |

FCS 5000 |

HDFF–120 |

|

Ø 150 mm (5.91 in) |

FCS 7500 |

HDFF–150 |

|

Ø 195 mm (7.68 in) |

FCS 10000 |

HDFF–195 |